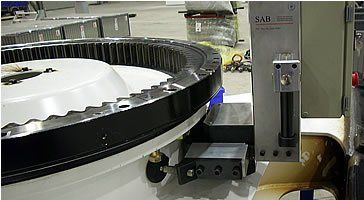

Main bearing cross-anchor

hand-held tightening systems

Moves almost by itself

Put on a little hand

Many industries require precision machinery for bolting assembly parts in a production line. It is often necessary to measure and document the bolting data. In addition, we attach importance to high-quality components and ergonomics. We always build as small and as light as possible. Further down you will find examples of different screwdriving machines and applications. In terms of design, the required torques play a subordinate role for us because we have experience with a wide variety of implementations. Again, we like to rely on the variant design. This guarantees reliable systems and reduces maintenance.

Technical specifications:

Technical specifications:

Technical specifications:

Technical specifications:

Technical specifications:

Technical specifications:

Technical specifications:

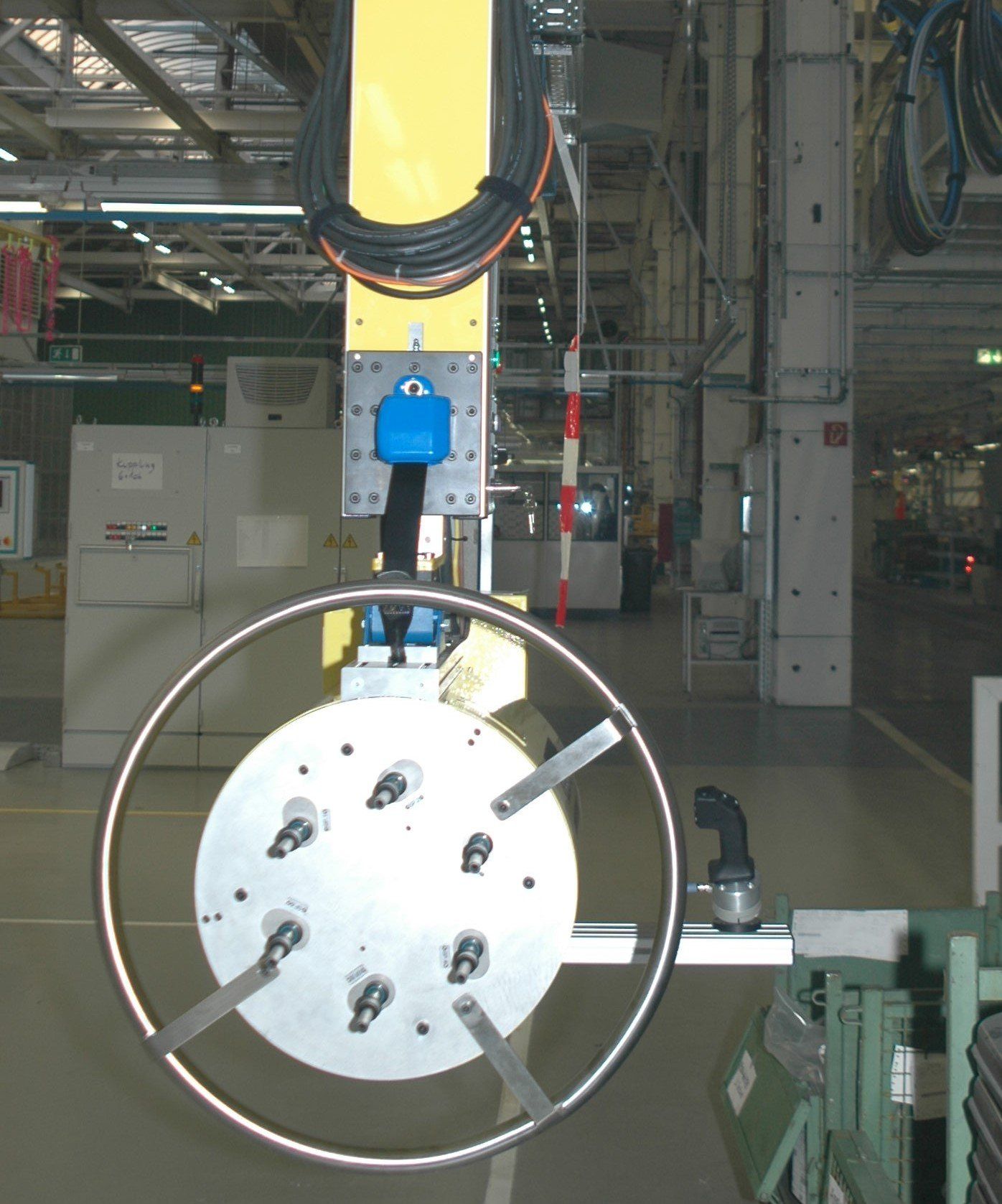

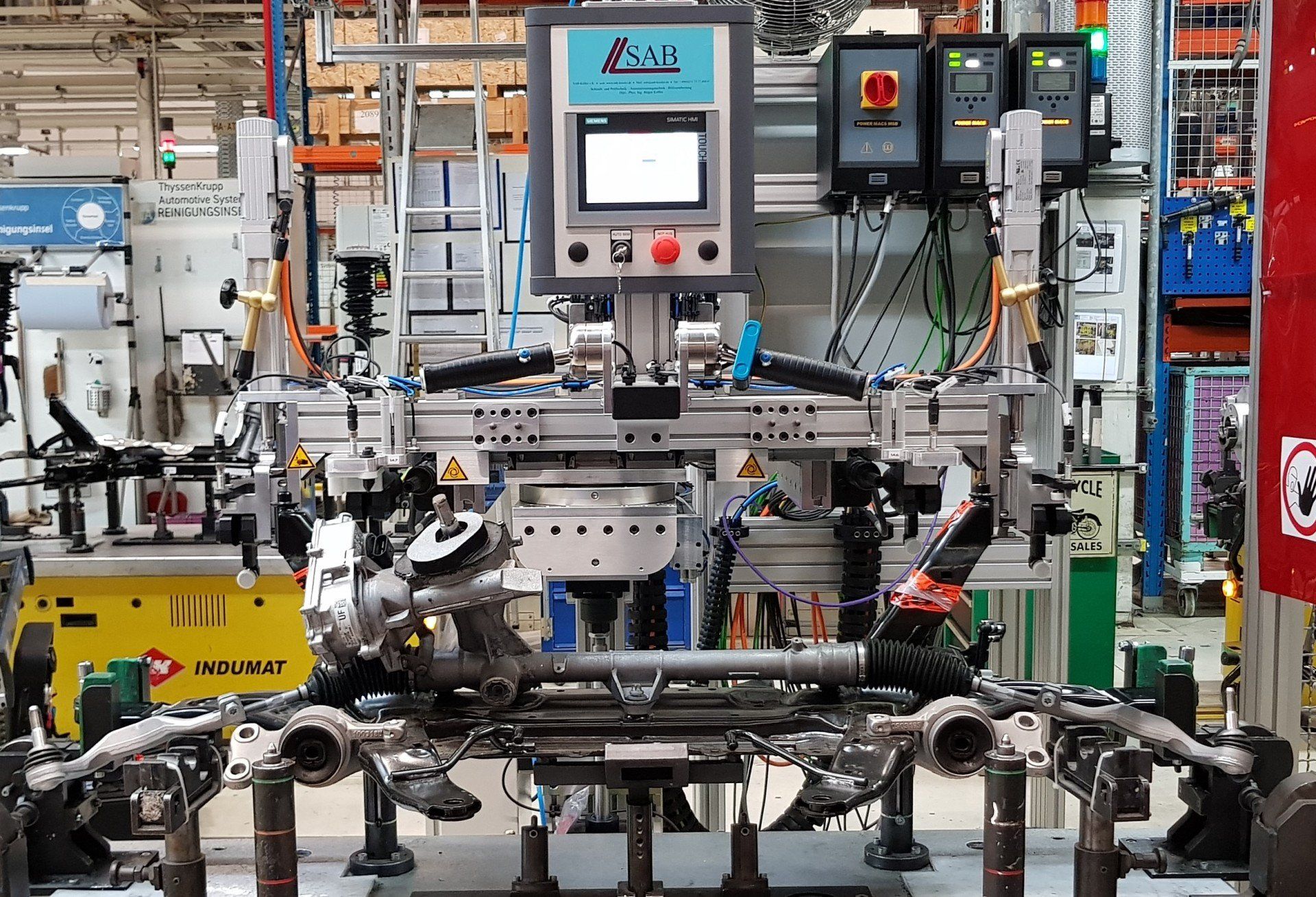

Technical data: Base frame with protective hood and light curtain for the loading areaHydraulic clamping device for coupling receptionHydraulic tension of the ball1000 Nm Power wrench with torque angle controlMaximum torques: 600 Nm

Technical specifications:

Technical specifications:

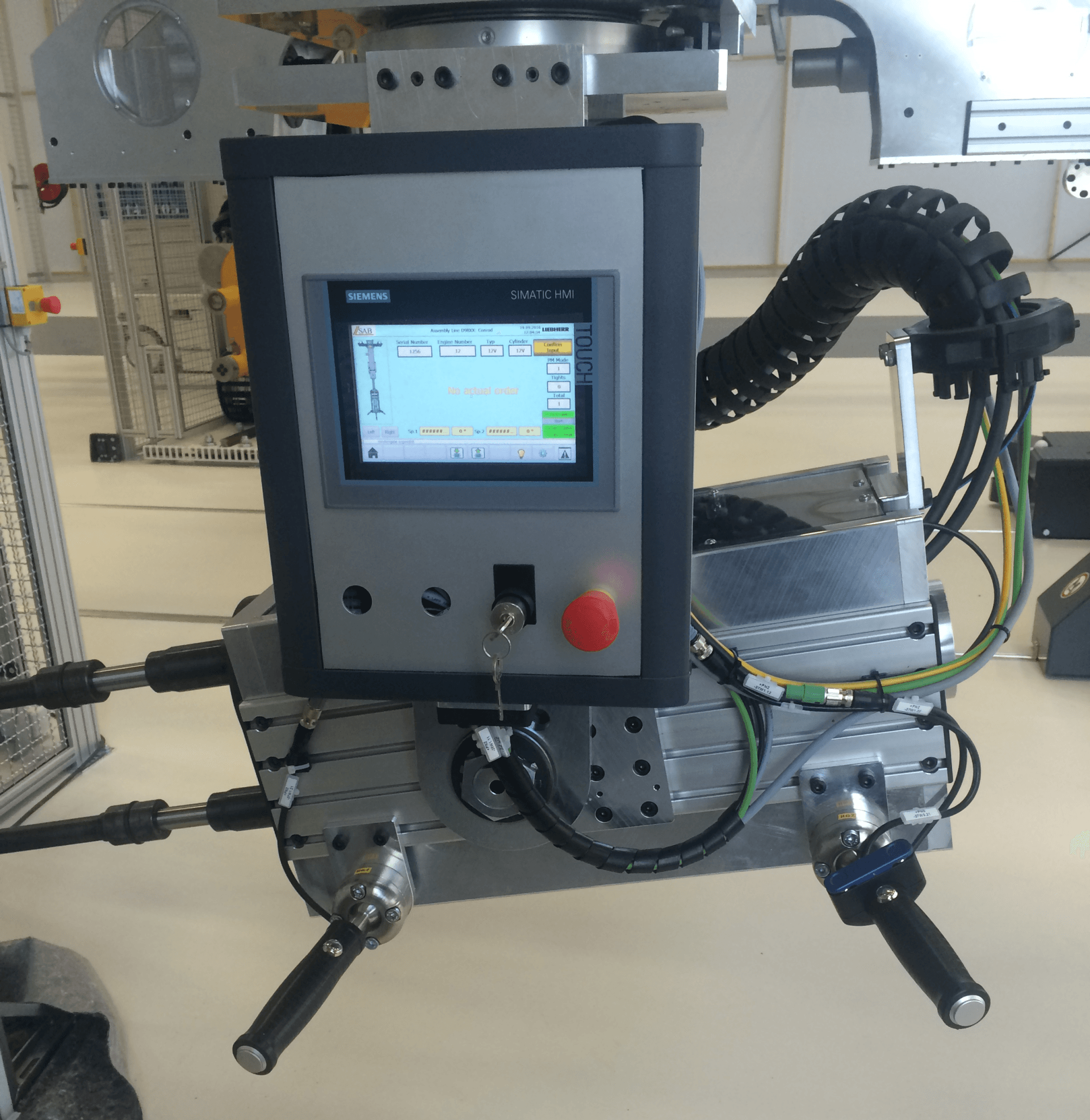

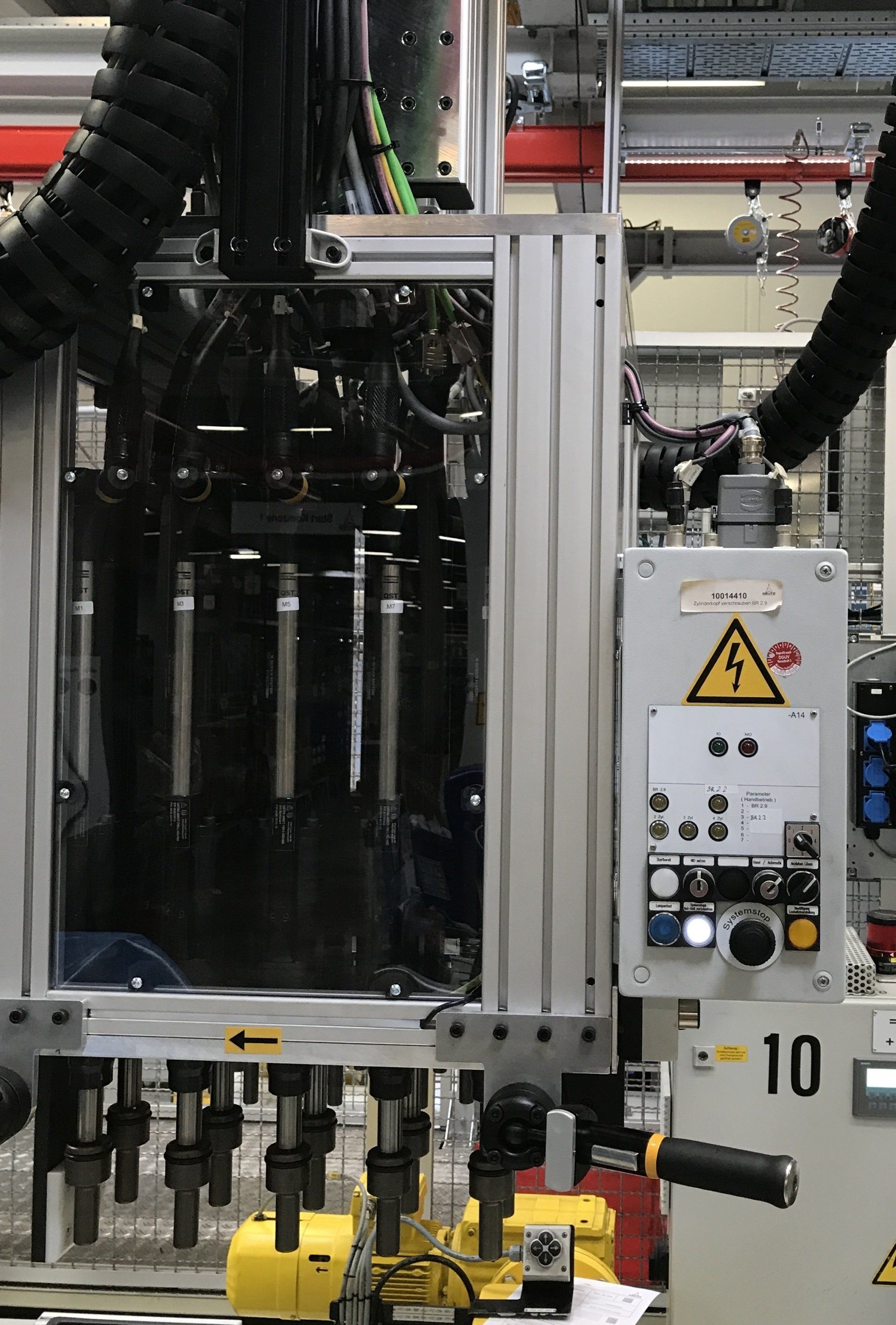

Technical data: Each output has a device for the installation of a reference sensor for the measurement of the torquesThe entire unit is hand-guided with electrical support. With the weight of approx. 800 kg an automatic tracking was necessary. Max. Torque: 630 Nm

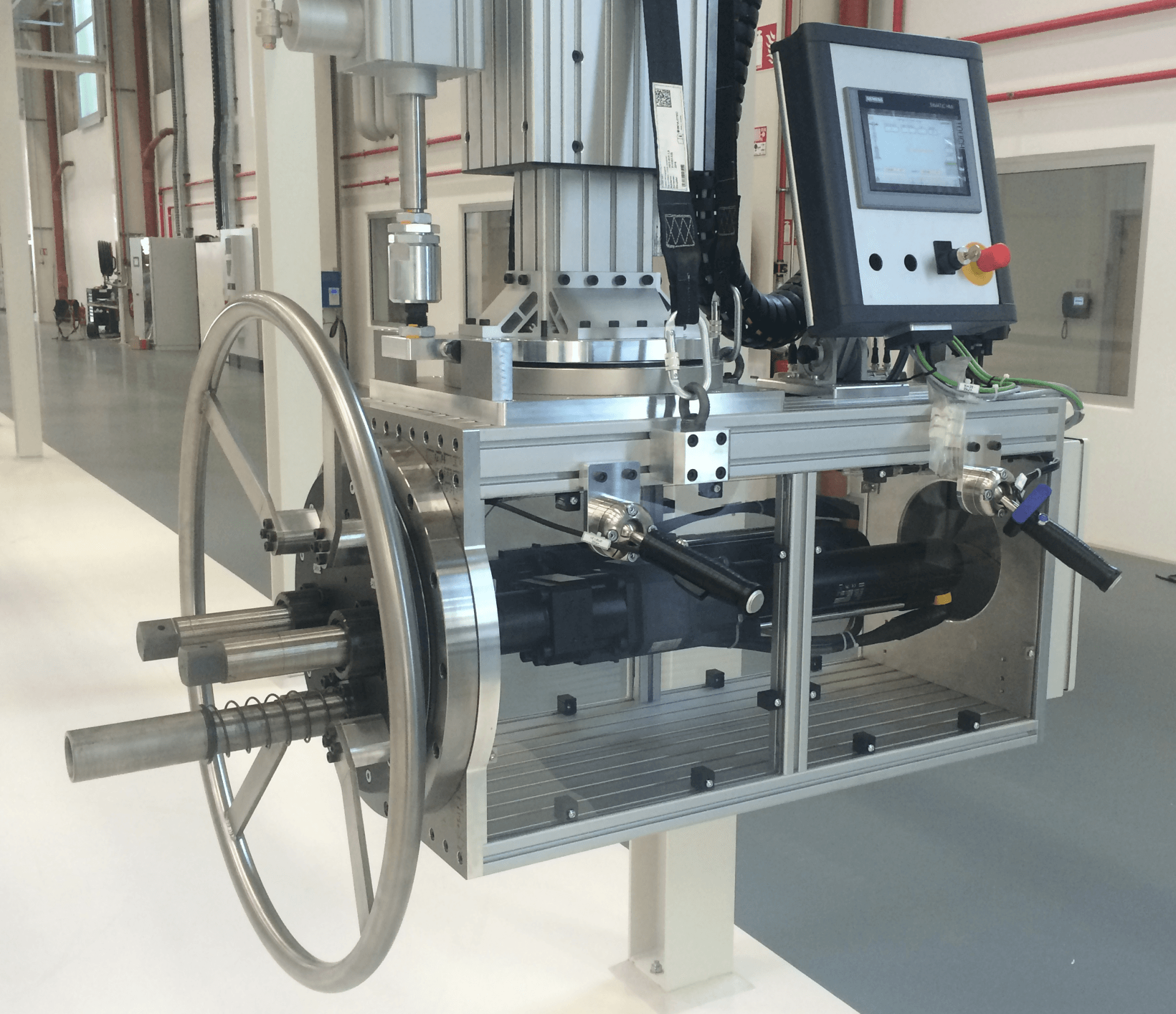

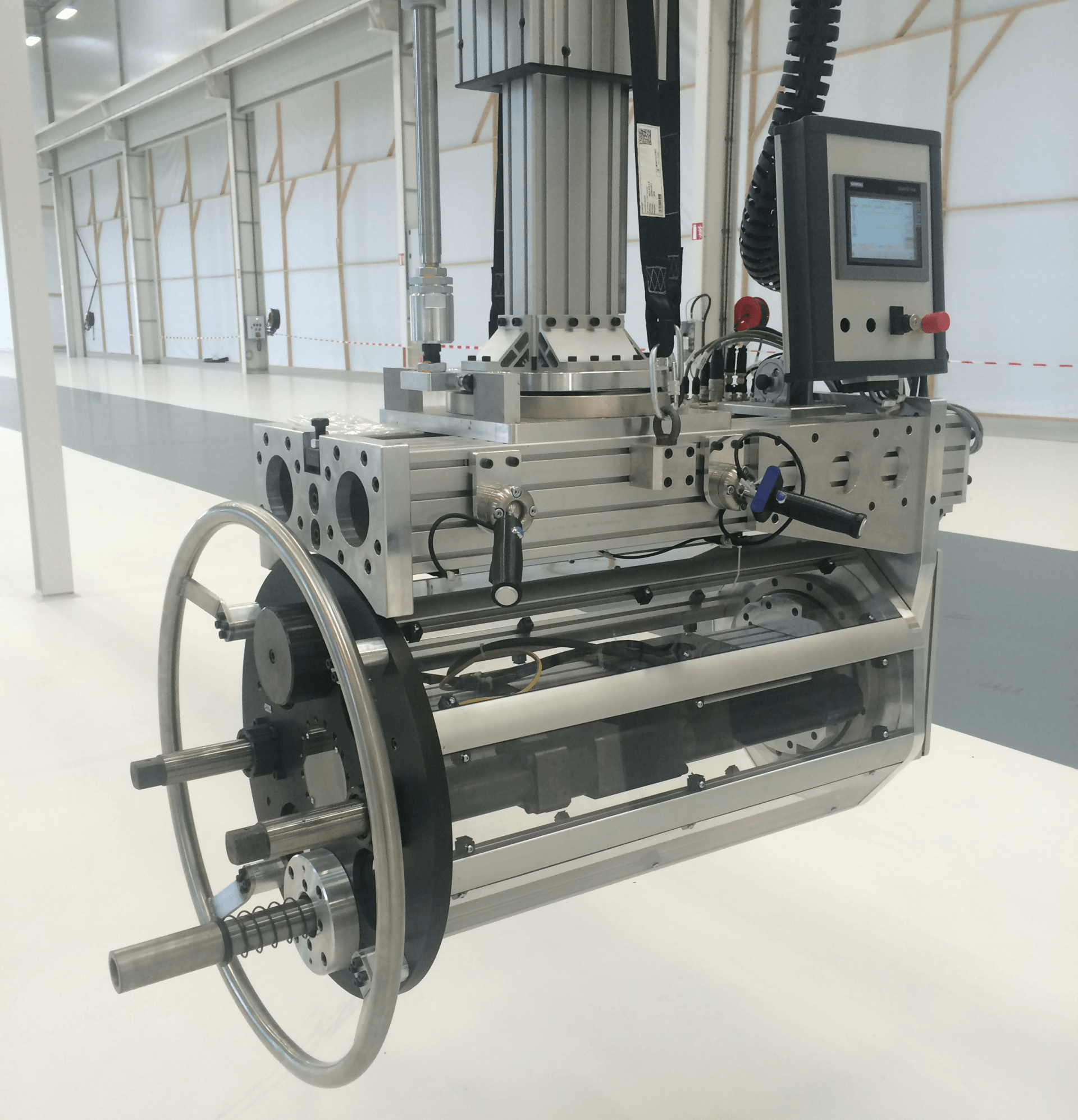

Technical data: 26-speed special gearbox, as screw pitches were so small that standard offset gearboxes were too largeDivision per output: 1: 3Visor adapter for drive spindlesSize: 1200 mm x 500 mm x 150 mmGear ratio 1: 3.5Input torque max. 210 NmOutput torque max. 630 Nm Efficiency> 0.93 Repeat accuracy <2% Permanent disposable lubrication

Technical specifications:

Technical specifications:

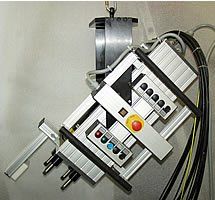

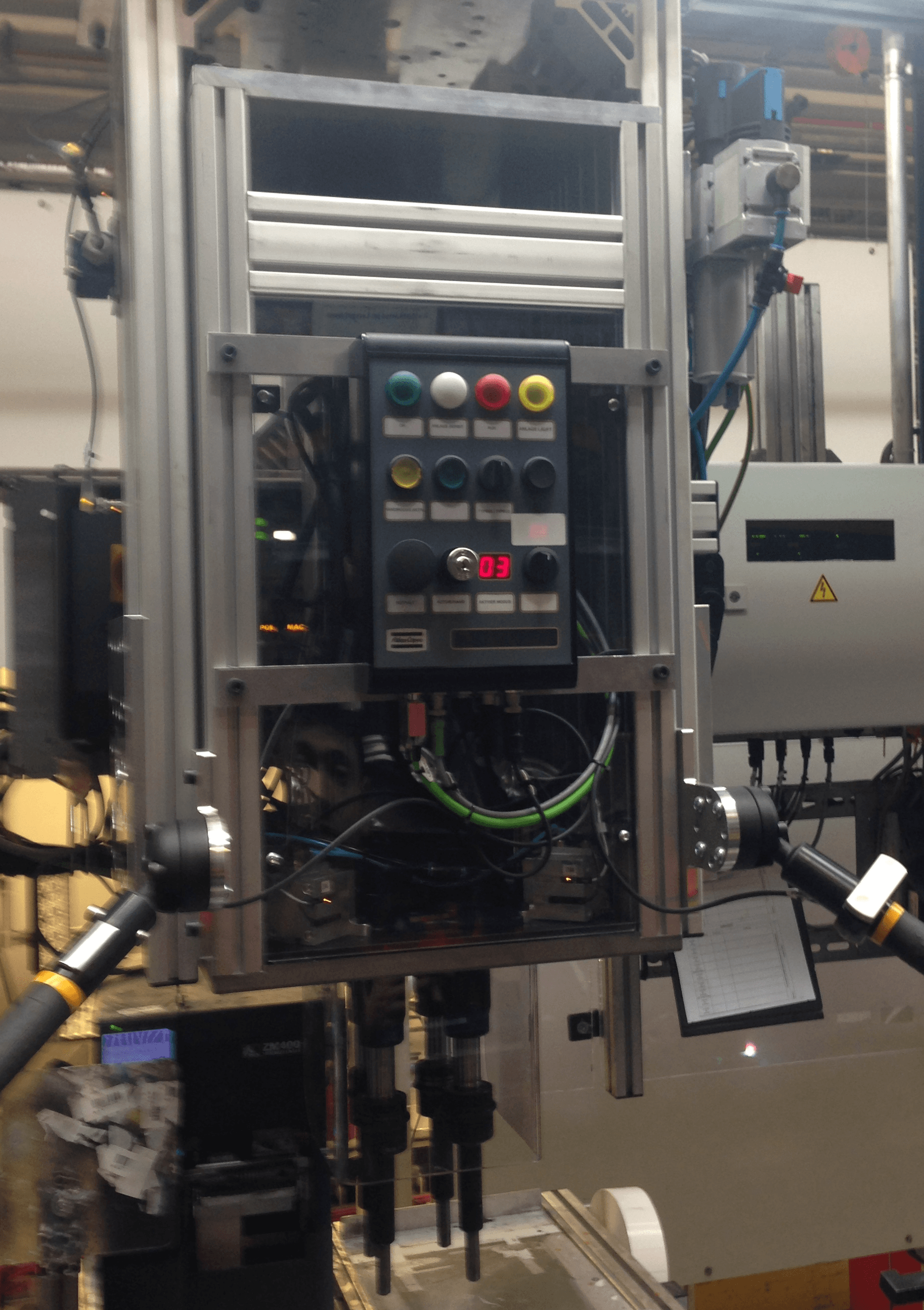

Technical data: All buttons are easily accessible with the thumb of each handWrench mechanism verticalMaximum torque: 950 Nm

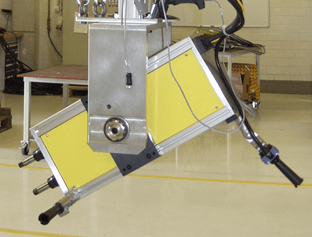

Technical data: Fixed pitchSwingableThe screw unit is swiveled via pivot bearings on the sides of the screwdriver. Adjustable friction brakes can be used to set the actuating forces for the pivoting movement. This keeps the nutrunner in any position Maximum torque: 580 Nm

Technical data: Fixed gauge The screwing point is inclined, so that an insertion aid facilitates the feeding of the screwdriving unit Guide and support support Maximum torques: 950 Nm

Technical specifications:

Technical specifications:

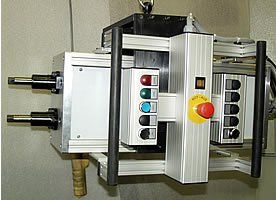

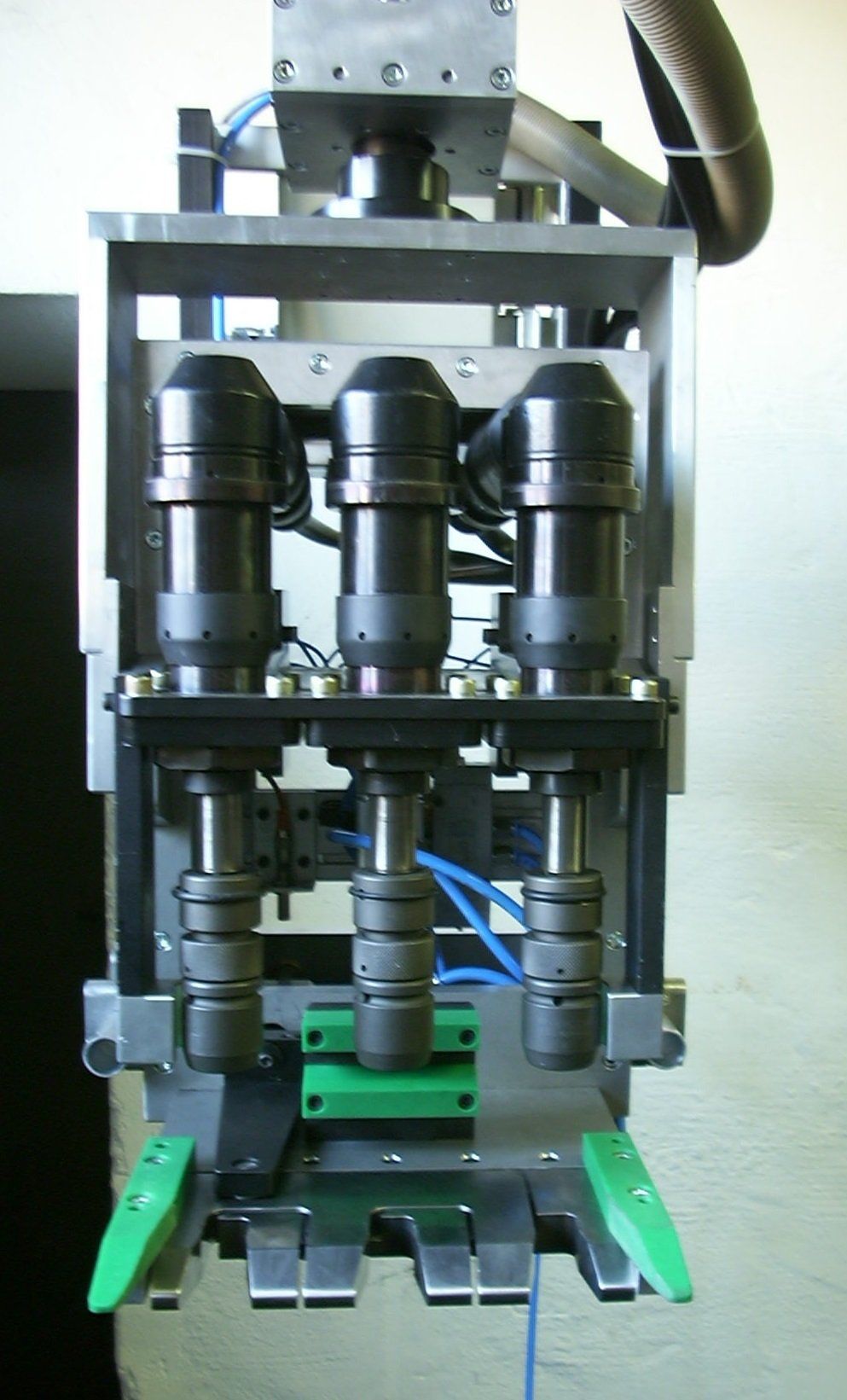

Technical data: 3 nuts must be countered 3 Angle screwdrivers in a mounting frame 3-fold clamping device for the locknuts Maximum torques: 350 Nm

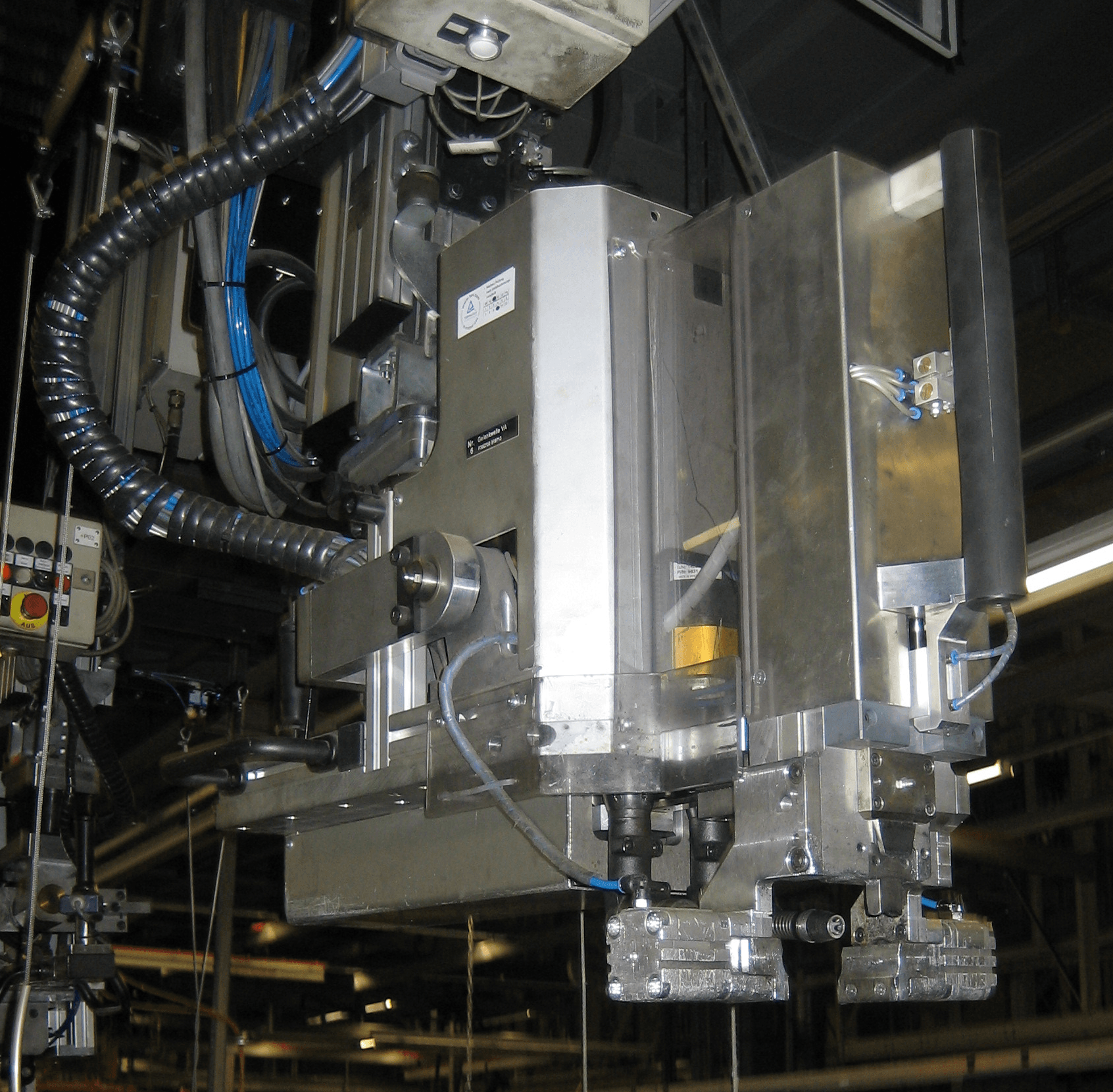

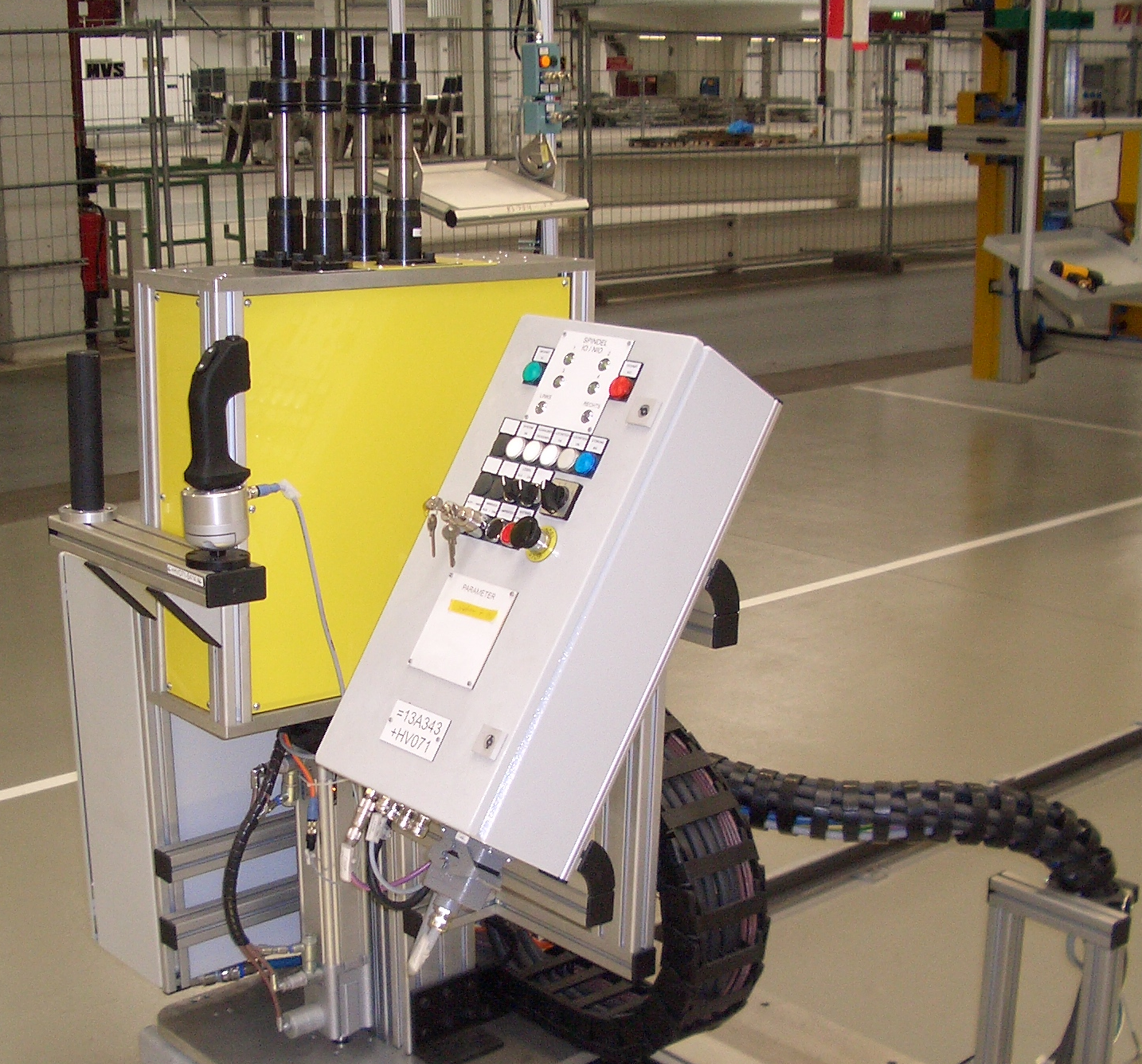

Technical data: Trolley with chain hoist and rail system for displacement in XY plane.All system components are made of aluminum, the load-critical made of high-strength aluminum.Maximum torques: 1000 NmWrench drives to 500 mm lengthStichmaße 95 to 300 mm are standard, others on request

Technical specifications:

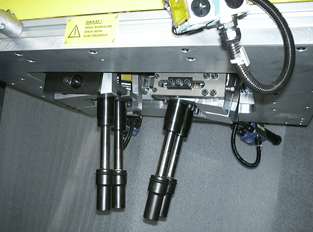

Technical data: Fixed pitch dimension Floor guide Connection to the screw point from below Crossing manually on rails Longitudinal travel on floor rails, sunk into the floor Maximum torques: 320 Nm

Technical data: Thanks to a specially developed rotary-swivel device, we have realized the movements almost without play. This was necessary to prevent the Torx screws from slipping during screwing. Pneumatic finger secures the unit to the workpiece. Maximum torque: 200 Nm

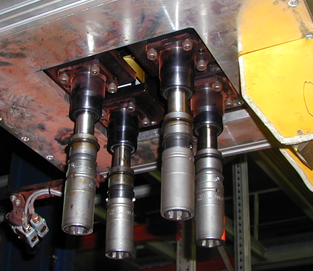

Technical data: 4-fold U-bolt screwdriver (rear axle on leaf spring) Adjustable stitch dimension Floor guide Coupling to the screw point from below Crossing manually on rails Longitudinal travel on floor rails, sunk into the floor Maximum torques: 320 Nm

Technical specifications:

Technical specifications:

Technical data: 2 pitches for various types of couplings can be mountedAll adjustment units with recirculating ball bearingsLive time lubricationMaximum torques: 50 Nm

Technical specifications:

Technical specifications:

Technical specifications:

Technical specifications:

Technical specifications:

Technical specifications:

Technical data: For more information, please visit our page Screwdrivers. Thanks.

Technical specifications:

Technical data: 4-fold spring-bolt wrench Adjustable pitch with inclination adjustment To avoid bending forces on the standard wrench, special support extensions are used Maximum torques: 320 Nm

Technical data: Adjustable stitch sizeTo avoid bending forces on the standard screwdrivers, special support extensions are usedMaximum torques: 1,200 Nm

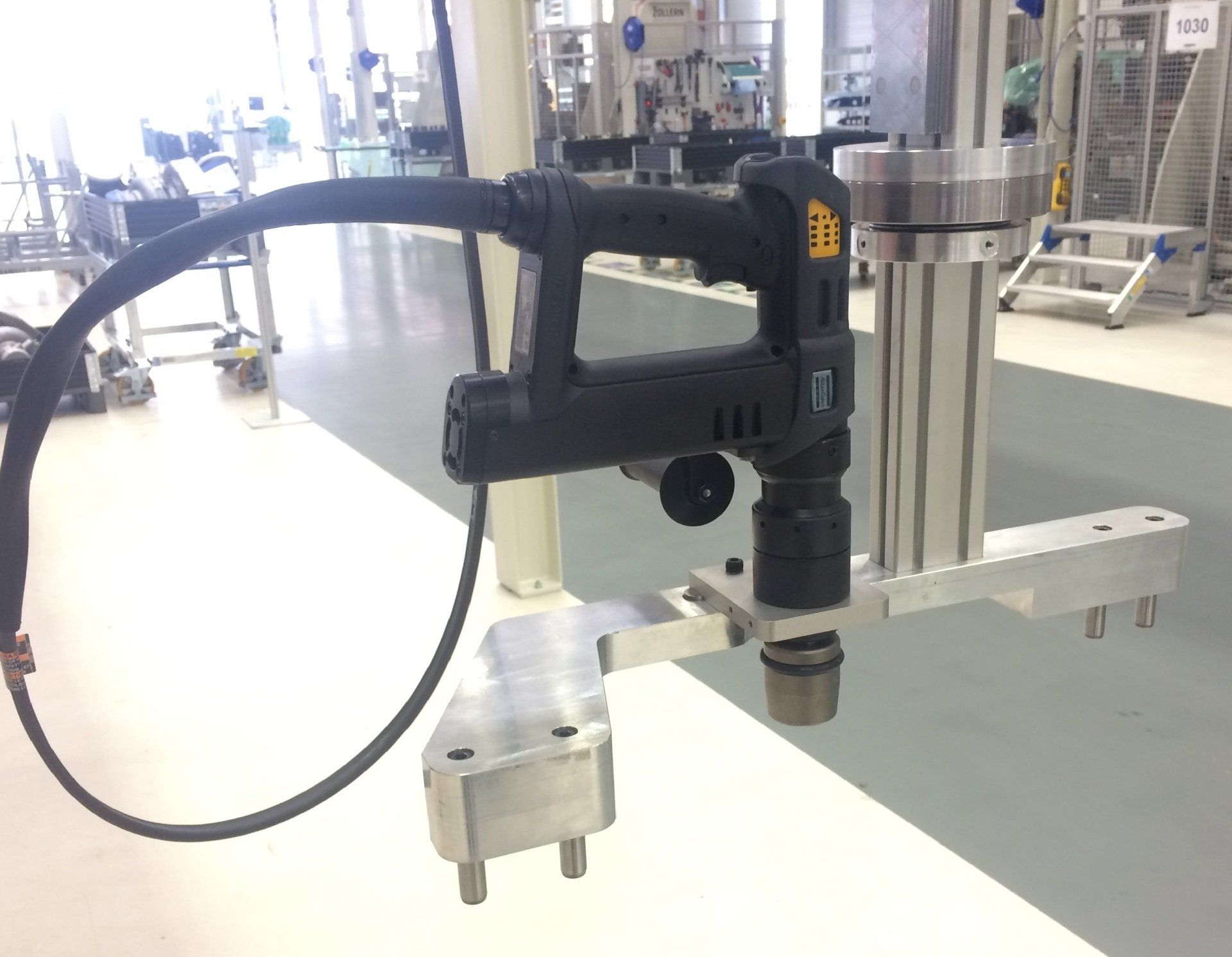

Technical data: The screwdriver has not been planned as a multiple screwdriver due to the different components. The reaction torques must therefore be absorbed by the entire system via a telescope Maximum torques: 150 Nm

Technical data: Maximum torques: 150 Nm Screwdriver mechanism inclined

Technical data: Fixed pitch pivotable Screwdriver mechanism tiltable via adjustable friction bearings Maximum torques: 580 Nm

Technical data: Maximum torque: 1,650 Nm Special gear head radius: 30 mm

Technical data: Maximum torque: 1,650 Nm Special gearhead head radius: 30 mm Complete control in the vehicle

Technical data: Infeed dimension adjustment for different chain rollers Component identification by barcode scannerGaszugfeder for tracking during the screwing

Technical data: Maximum torques: 4,000 NmAdjustable support on the swivel arm to absorb the reaction moments on adjacent screw headsComplete control in the trolley

Technical specifications:

Technical specifications:

Technical specifications:

Technical data: Screwdriver mechanism rotatable by /- 45 ° around its own axis. Car with telescope and cross slide system for displacement in XY plane

Technical data: Movement on heavy-duty ball circulating units.Manufacture by pneumatic.Vertical telescopeCross-pass manually on railsLongitudinal movement on floor rails, sunk into the ground

Technical data: With pneumatic balancer and cross rail vehicle feed unit pneumatically to the vehicle.

Car battery manipulator that places the workpiece exactly where it needs to go and without scratching the vehicle.

Replacement wheel manipulator, which places the spare wheel in the boot so that no scratches occur on the bodywork.

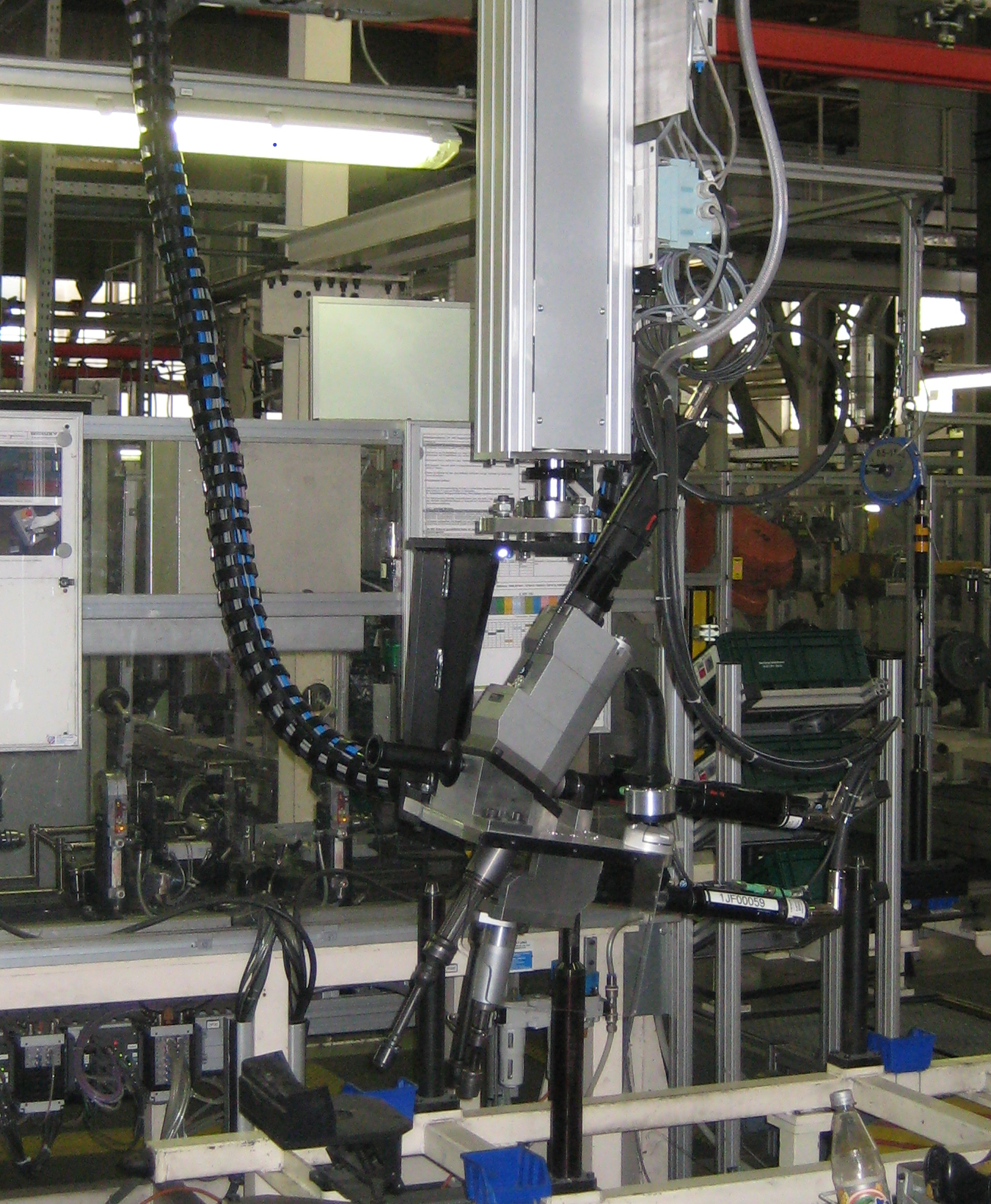

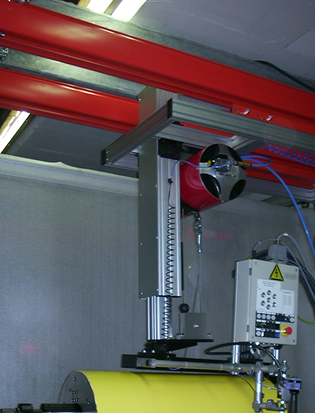

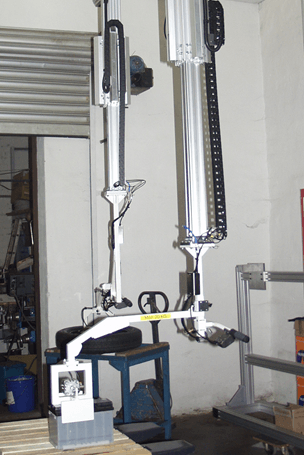

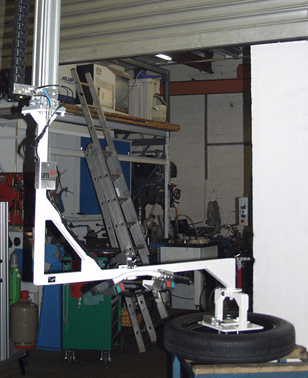

Technical data: Column manipulator for high-torque wrenches Special gearbox for reaching the bolting point There are systems for 600 Nm and 1000 Nm. Swing range approx. 2.5 m maximum Maximum trailer load 100 kg

Technical data: Column manipulator for high-torque wrenches Special gearbox for reaching the bolting point There are systems for 600 Nm and 1000 Nm. Swing range approx. 2.5 m maximum Maximum trailer load 100 kg

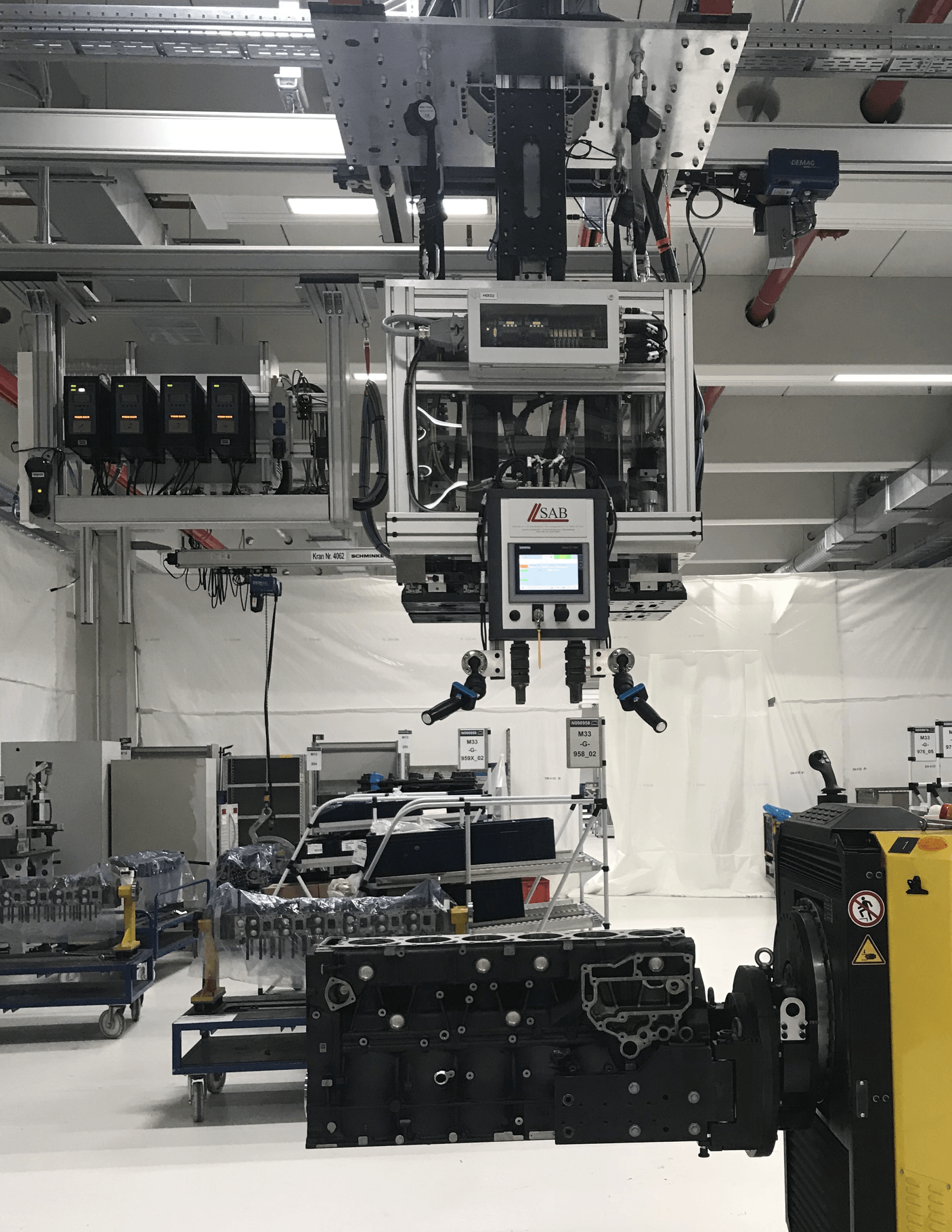

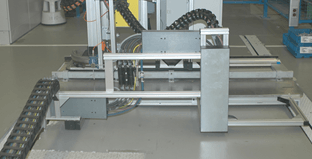

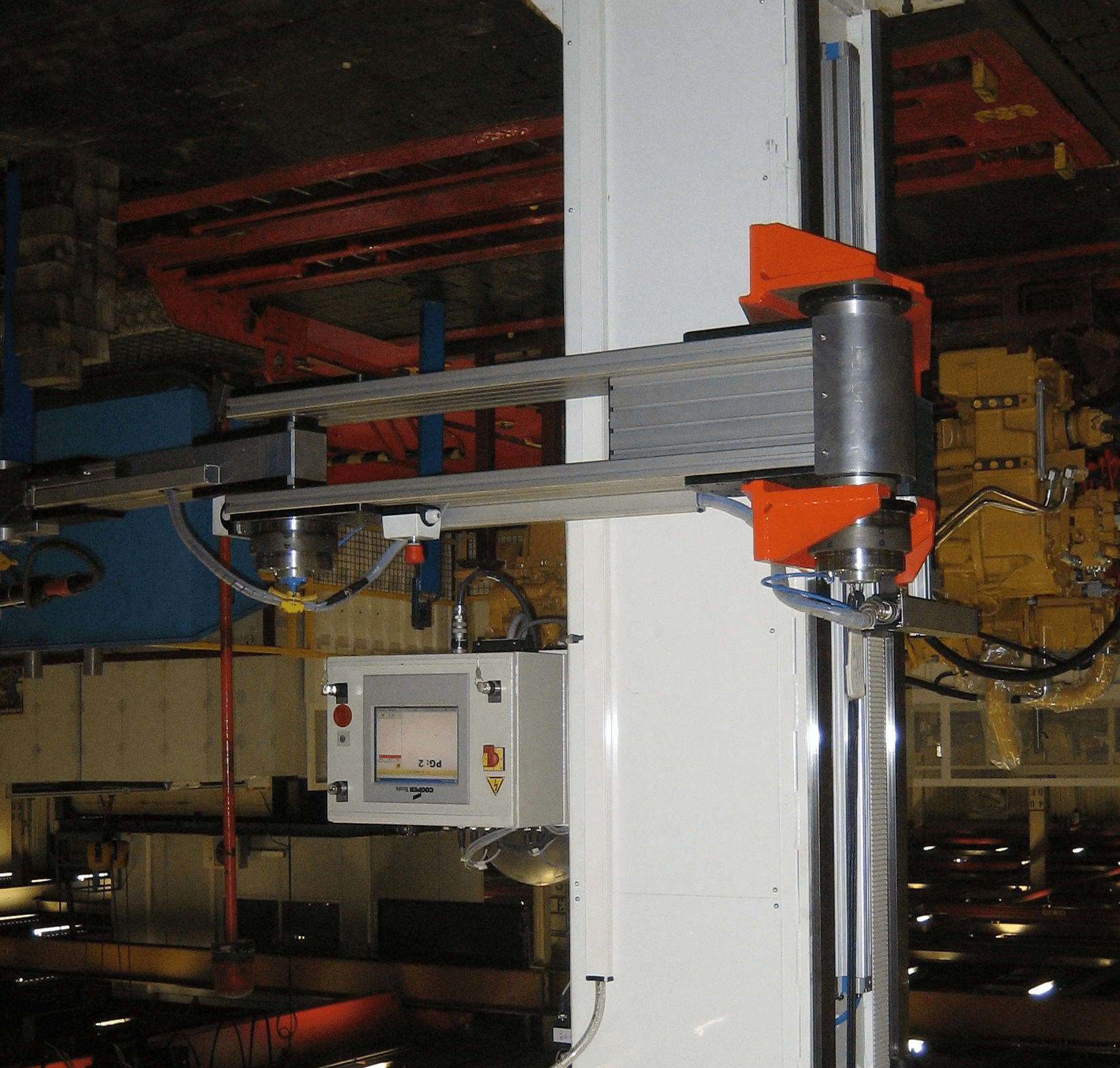

Technical data: Gantry manipulator for high torque wrenches Torques up to 2500 Nm. Portal width 4 m Portal height 3.5 m Telescopic lift vertical 500 mm Telescopic lift horizontal 1.5 m Special gearbox for narrow interfering contours